Signs You Need Make-Up Air

Introduction

The lack of make-up air in a building can cause serious problems. Many times the problems are not even recognized and show themselves in ways that most people do not think about. A properly designed and installed ventilation system provides environmental control by avoiding negative pressure. Uncontrolled infiltration of air through window sashes, doors and

Read MoreTaylor Products

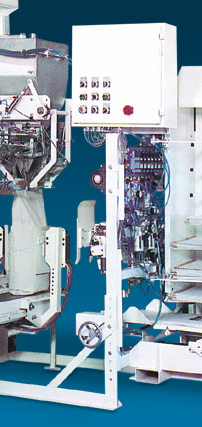

Fluid Engineering is proud to represent Taylor Products, division of Magnum Systems, a leader in the design and manufacturing of packaging automation systems and equipment.

Fluid Engineering is proud to represent Taylor Products, division of Magnum Systems, a leader in the design and manufacturing of packaging automation systems and equipment.

Taylor Products offers a broad range of modular packaging components engineered to perform alone or as a totally integrated packaging process system. Its offering includes open mouth bag filling, valve bag filling, intermediate bulk loading and unloading, and vertical form fill seal packaging equipment.

With a weight range from 2 ounces to 2 tons and a material range that includes flowing granules to fragile powders Taylor Products and Fluid Engineering have the experience and equipment to provide the right solution for your application.

![]()

Taylor Products manufactures a wide range of electronic valve bag packers which can be readily adapted to handle a variety of dry materials. Each model is engineered for easy operation with practical features and construction to perform in plant conditions.

Each valve bag bagging machine has been specifically designed to handle different materials. From seed and plastic pellets to clays and cement adhesives there is a valve bagging machine that can handle your material efficiently.

Taylor's modular fabrication keeps the equipment reasonably priced, while enabling the production of complex units and systems for your specific needs. Options on these machines include stainless steel construction, and the cutting edge T3000 weigh controller.

![]()

Robotic Bag Placer — Winner of the 2005 Powder Bulk Solids Innovation Award.

Robotic Bag Placer — Winner of the 2005 Powder Bulk Solids Innovation Award.

The TRV1000 is the latest in innovation from Taylor Products. This placer offers the latest in robotic technology through Taylor Product's unique relationship with FANUC Robotics. FANUC is the world's largest robotics producer, and has built a reputation for cutting edge technology. The placer is capable of placing bags on multiple machines, being mounted in multiple positions, and customizable to your specific application. For more information please click on the PDF link below.

- Direct labor savings and improved personnel scheduling and utilization

- Multiple mounting positions, compact size and small footprint facilitate placement in tight surroundings

- Dust and water resistant design maximize durability

- Flexibility to handle multiple sized products with one robot

- Requires minimal programming and maintenance

![]()

Ultrasonic Valve Bag Sealer

Ultrasonic Valve Bag Sealer

Taylor Products, division of Magnum Systems, announces the release of the TRU Seal ultrasonic valve bag sealer. The TRU Seal has been specifically designed to work with Taylor valve bagging equipment and incorporates the latest ultrasonic sealing technology. For more information please click on the PDF link below.

Seal Valve Bags with Innovative Ultrasonic Technology

- Ultrasonic waves alter molecular structure of sealing agent without heat which reduces product degradation

- Rigid mount set-up at filling source decreases amount of bag movement while maintaining bag shape

- Ultrasonic waves displaces product from seal area providing a clean positive seal

- Helps prevent product loss during shipping

- Capable of both plastic and paper valve sealable bags

- Works well with dusty, fluid, powder, and hydroscopic products

![]()

Economical Packing for all Free-Flowing Materials

Economical Packing for all Free-Flowing Materials

The Taylor GW Series Auger Packer is excellent for bagging a wide range of products: seeds, resins, plastics, sand, rubber granulars, fertilizers and abrasives. Self-cleaning design facilitates change of products without contamination. Practical design makes the GW Series transportable and adaptable to existing construction. To operate, place bag on spout and pull gate handle to start fill - shuts off automatically. When bag is full, press foot lever to remove bag.

![]()

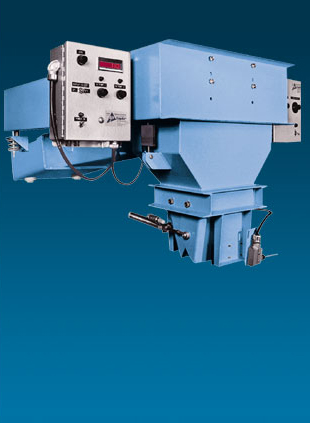

Valve Bag Air Packer

Valve Bag Air Packer

Taylor Products' Model A Packers are pneumatic aeration packers designed specifically for powders and powder mixes, such as flour, cement, and chemicals, although they effectively handle granular materials too. The Model A was the first packer with Taylor's precise bulk and dribble fill cycles. For more information please click on the PDF link below.

Package powder and powder mixes with speed and precision

- 15 lb to 125 lb capacity for valve bags

- Sugar (powder and granular)

- Flour

- Cement

- Various oxides

- Refractory Mixes

- Fine Resins

![]()

Valve Bag Air Packer

Taylor's Model C Packers are engineered for most granular, free-flowing materials, such as seed, fertilizer, plastic pellets, grain and sand. These pneumatic packers introduced Taylor's patented reverse flow, and are designed to yield exact measurements at high speeds. For more information please click on the PDF link below.

Package granular and free-flowing materials with speed and precision

- 15 lb to 125 lb capacity for valve bags

- Certified seeds

- Fertilizers

- Plastic pellets

- Grains

- Sand

![]()

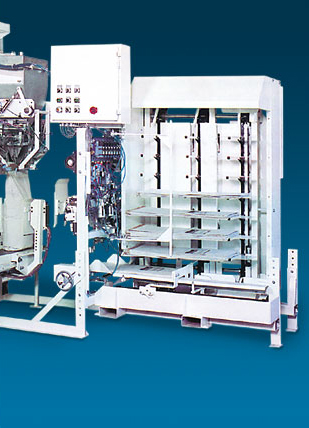

Taylor Products manufactures a variety of open mouth bagging solutions. From the economical to the incredibly accurate, they have the right equipment for your application. There offering includes eleven different models all designed to handle different types of materials with accuracy and efficiency.

Taylor Products manufactures a variety of open mouth bagging solutions. From the economical to the incredibly accurate, they have the right equipment for your application. There offering includes eleven different models all designed to handle different types of materials with accuracy and efficiency.

![]()

Electronic Open Mouth Bag Placer

Electronic Open Mouth Bag Placer

The Taylor Model TOMP Automatic Open Mouth Bag Placer will position kraft and/or poly bags on the spout of an electronic bagging scale. It is capable of placing up to 15 bags per minute, and can be modified for use with gross weigh or net weigh scales. The magazine can be easily loaded while the machine is in operation. It is compatible with a variety of weighing scales, and can be purchased separately or with other equipment to create fully automated bagging systems. The TOMP comes fully assembled, pre-hosed and wired for operation.

![]()

Open Mouth Bag Scale

The OM2 Series scale utilizes Taylor’s patented beam scale is self dampening, and the weight pointer and calibration adjustment are located directly on the beam. The OM2 Series flow control regulates the speed of material going through the scale. The series includes both manual and automatic models.

Simple but Accurate Weighing on Patented Beam Scale Design

- Up to 12 bags per minute

- 15 lb to 125 lb capacity

- Granules

- Feed

- Seed

- Corn

![]()

Compact Electronic Bagging Scale

Compact Electronic Bagging Scale

Taylor Product's TE 100 includes more features than most large scales. The operator simply sets the weight and hangs the bag. The unit clamps the bag in place, fills, checks the weight, and drops the bag. For more information please click on the PDF link below.

Innovative Compact Electronic Scale with Self-Correcting Precision

- 20 lb to 125 lb capacity

- Granulars

- Bulk and Dribble Flow Gate

- Compact Design

- Up to 14 weighments per minute

![]()

Vibratory Feeding Net Weigh Scale

Taylor Products' TE10 is an electronic, small net weigh scale designed for weighments of 2 oz to 5 lb. The TE10 was designed with a timed discharge to eliminate spillage, as well as controls for single operator convenience. For more information please click on the PDF link below.

Variable Speed Electronic Scale for Small Accurate Weights

- 2 oz to 5 lb capacity (Weight range is dependent on product's bulk density.

Free product testing recommended.) - Granulars

- Powders

- Up to 20 weighments per minute

![]()

Open Mouth Bag Vibratory Feeding Scale

Taylor's VG Series bagging scale weighs products of variable density or erratic flow characteristics with extreme accuracy. It utilizes a large electronic vibrating pan feeder that has adjustable two-speed feed rate. Simply position the bag and fill, trim, stop and drop are all automatic. For more information please click on the PDF link below.

Bag Variable Bulk Density and Erratic Flowing Materials with Precision

- 15 lb to 125 lb capacity

- Erratic feeding materials

- Variable bulk density materials

- Gross weigh scale

- Two speed feed rate

- Up to 8 bags per minute

![]()

Gravity Fill Scale

Specifically engineered for free-flowing products, the Taylor GN Series electronic net weigh scale will operate at speeds up to 12 bags per minute for 20 to 110 lb. weighments. The system features 4 cubic foot weigh bucket with dual electronic load cells, bulk and dribble flow gates, air cylinder operated bag clamps and dust enclosure with 4-inch dust pickup. The TEGN is available with 304 stainless steel product contact parts and/or automatic zero tare feature. Duplex models with 22 weighments per minute also are available.

- 20 lb to 110 lb capacity

- Bulk and Dribble Fill

- Free Flowing Products

![]()

Open Mouth Bag Vibratory Feeding Scale

Open Mouth Bag Vibratory Feeding Scale

The VN Series has been designed for difficult to feed or fragile materials. The VN includes a large vibratory feeding pan with a two-speed fill rate which moves a large volume of material quickly and gently. All functions and controls of the VN are automatic. For more information please click on the PDF link below.

Weigh Difficult to Feed and Fragile Materials with Ease and Accuracy

- 15 lb to 125 lb capacity

- Difficult to feed materials

- Fragile materials

- Net weigh scale

- Two speed feed rate

- Up to 12 bags per minute

![]()

Open Mouth Bag Auger Filler

The Taylor Model APO is designed to handle powder products that are aerated, bind, cake, or bridge easily. The variable speed auger option utilizes Taylor’s “bulk and dribble” technology and ensures a fast and accurate weight measurement.

Package Difficult to Feed or Control Materials with Speed and Precision

- 15 lb to 125 lb capacity

- Flours and starches

- Industrial chemicals

- Oily products with low bulk density

![]()

The Taylor Model APO Dual is designed with variable speed augers perfecting the art of "bulk and dribble" feeding. This technology allows the packer to feed material at three sequential speed settings which produces faster and more accurate measurements. For more information please click on the PDF link below.

Package material which is difficult to feed or control with speed and precision

- 15 lb to 125 lb capacity for bags, drums, and boxes

- Flour and starches

- Industrial chemicals

- Sandy cement grouts

- Chili powder blends

- Cakey flours

- Oily products with low bulk density

![]()

Open Mouth Bag Impeller Packer

The Taylor Model IPO was designed for practical performance on heavy, dense, difficult-to-feed powders, and fine granular mixtures. The Model IPO utilizes felt split shaft seals on the rotating impeller and feed screw drive shaft to prevent leakage and screws are used to keep the material flowing loaded into the impeller blades.

Package Heavy and Dense Materials with Speed and Precision

- 15 lb to 125 lb capacity

- Grout Mixes

- Cement

- Stucco

- Clays

- Fly Ash

- Limestone

![]()

Box / Drum Filler

Box / Drum Filler

The Taylor VB Series is engineered to accurately fill boxes, small drums, pails and buckets. Features include 15 cubic foot product hopper, adjustable two speed vibratory feeder and roller scale base with electronic load cell. Unit is mounted on heavy duty support frame. Foot operated start switch is standard. Requires 110 volt single phase electrical service. VB Series options include stainless steel product contact surfaces, photo-electric eye start activator, dust enclosures, automatic container discharge and feeder cutoff gate. Indexing conveyor for fully automatic operation also available.

Taylor's bulk weighing and discharging equipment are engineered for a variety of materials. The Bulk Storage Filler's modular design allows complete flexibility from a free standing manual operation to a fully integrated and automated system.

The Bulk Bag Unloader is adaptable to nearly any discharge or deweigh application. It is constructed of heavy tubular steel with a compact footprint of 60 in by 60 in. The bulk bag unloader can be easily modified with any of its multiple options in order to handle your specific requirements.

Your bulk bag system can be completed with Taylor's Flexible Auger Conveyor. It is a simple but ruggedly designed conveyor with one moving part. It has the capability of transporting a wide range of free flowing powders, granules, or pellets safely and reliably anywhere in your plant.

![]()

Bulk Bag Unloader

Taylor's IBC2000 is adaptable to nearly any discharge or deweigh application. It is constructed of heavy duty tubular steel with a compact footprint of 60 in by 60 in. The IBC2000 can be easily modified with any of its multiple options in order to handle your specific requirements. For more information please click on the PDF link below.

Complete Bulk Unloading with Simplicity and Flexibility

- 100 lb to 4,000 lb capacity

- Granulars

- Powders

- Compact design

- Easily adaptable to custom applications

![]()

Bulk Bag/Box/Drum Packer

Taylor's IBC 3000 Packers are engineered for a variety of materials and containers. The IBC's modular design allows complete flexibility from a free standing manual operation to a fully integrated and automated system handling bags, drums, and boxes. For more information please click on the PDF link below.

Complete Bulk Storage Automation with Simplicity and Flexibility

- 100 lb to 3,000 lb capacity (Weight range is dependent on product's bulk density. Free product testing recommended.)

- Granulars

- Powders

- Fill drums, bags, and boxes

- Compact modular design

Taylor Products is committed to providing consumers with innovative packaging solutions. This drive has led Taylor to its latest innovation: robotics. While many industrial companies utilize robotics, Taylor Products is leading the way in the packaging industry. This includes robotic bag placing and palletizing.

Taylor can offer the latest in robotic technology through their unique relationship with FANUC Robotics. FANUC is the world’s largest robotics producer, and has built a reputation for cutting-edge technology.

When combined you are left with a leading-edge packaging product, that reduces operating costs while increasing production output.

![]()

Robotic Palletizing System

The Taylor Products TRP3000 is the latest in innovation from Taylor Products. This robotic palletizing system offers the latest in robotic technology through Taylor Product's unique relationship with FANUC Robotics. Taylor Products has gained a reputation for innovative weighing and packaging equipment and FANUC is the world's largest robotics producer who has built a reputation for cutting edge technology. The result is a palletizing system that has been engineered for precision high-speed/high-payload operation, user-friendly setup, and maximum reliability. For more information please click on the PDF link below.

Robotic palletizing with speed and precision

- Direct labor savings and improved personnel scheduling and utilization

- Fastest cycle time and highest payload in robot class

- High performance motion yields fast cycle times and high throughput

- Flexibility to service multiple production lines

- Requires minimal programming and maintenance

![]()

Robotic Bag Placer — Winner of the 2005 Powder Bulk Solids Innovation Award

The TRV1000 is the latest in innovation from Taylor Products. This placer offers the latest in robotic technology through Taylor Product's unique relationship with FANUC Robotics. FANUC is the world's largest robotics producer, and has built a reputation for cutting edge technology. The placer is capable of placing bags on multiple machines, being mounted in multiple positions, and customizable to your specific application. For more information please click on the PDF link below.

- Direct labor savings and improved personnel scheduling and utilization

- Multiple mounting positions, compact size and small footprint facilitate placement in tight surroundings

- Dust and water resistant design maximize durability

- Flexibility to handle multiple sized products with one robot

- Requires minimal programming and maintenance

To get a quote, please contact us at (800) 841-9941.