Signs You Need Make-Up Air

Introduction

The lack of make-up air in a building can cause serious problems. Many times the problems are not even recognized and show themselves in ways that most people do not think about. A properly designed and installed ventilation system provides environmental control by avoiding negative pressure. Uncontrolled infiltration of air through window sashes, doors and

Read MoreFybroc

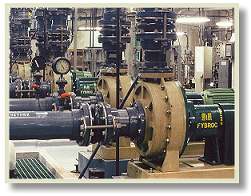

Fluid Engineering is the proud distributor of Fybroc fiberglass centrifugal pumps for all of Alabama and the following counties in Florida: Escambia, Santa Rosa, Okaloosa, Walton, Holmes, Washington, Jackson, Bay, Calhoun, Gulf, and Liberty.

Fluid Engineering is the proud distributor of Fybroc fiberglass centrifugal pumps for all of Alabama and the following counties in Florida: Escambia, Santa Rosa, Okaloosa, Walton, Holmes, Washington, Jackson, Bay, Calhoun, Gulf, and Liberty.

Fybroc manufactures ANSI process, self-priming and sealless mag-drive horizontal end-suction centrifugal pumps as well as vertical centrifugal sump pumps and cantilever sump pumps.

The Fybroc Advantage lies in its 35-year commitment to nonmetallic pumps and a continual spirit of innovation worthy of its title as the original manufacturer of fiberglass-reinforced pumps. Fybroc is the first manufacturer to adopt the resin transfer molding (RTM) method for production of its fiberglass-reinforced castings.

The primary benefit of this process is that it enables controlled installation of long strand fiberglass reinforcement and locations of high stress, delivering parts with superb physical properties. This enables the design and manufacture of thinner walled structures, allowing the application virtually pure resin systems for high level of corrosion resistance.

The primary benefit of this process is that it enables controlled installation of long strand fiberglass reinforcement and locations of high stress, delivering parts with superb physical properties. This enables the design and manufacture of thinner walled structures, allowing the application virtually pure resin systems for high level of corrosion resistance.

Standard methods of compression molding use chopped glass random reinforcement that deliver less strength than the RTM method. Additionally, the standard techniques with their inherent physical properties along with the exothermic properties of the highest quality resins force large quantities of clay filler into the bulk molding compound. The addition of these fillers adds no strength and reduces the corrosion resistance of the base resin.

The RTM method optimizes strength and corrosion resistance, while the compression molding process fails to enhance both.

Fybroc pumps include many other innovations that are industry firsts. Contact your Fluid Engineering sales or applications engineer today to learn more Fybroc fiberglass pumps.

| Markets Served Fybroc pumps have been used extensively to pump corrosive liquids in the following markets and applications.

|