Signs You Need Make-Up Air

Introduction

The lack of make-up air in a building can cause serious problems. Many times the problems are not even recognized and show themselves in ways that most people do not think about. A properly designed and installed ventilation system provides environmental control by avoiding negative pressure. Uncontrolled infiltration of air through window sashes, doors and

Read MorePenn Ventilation

Fluid Engineering,

Fluid Engineering,

Proudly Represents,

PENN ® Ventilation

Air Systems Company

Centrifugal Roof Exhausters

Ceiling and Inline Fans

Breezeway Exhaust Fans

Centrifugal Inline Fans

Gavity Ventilators

Centrifugal Blowers

Fluid Engineering, is proud to serve as a manufacturer‘s representative for Penn Ventilation fans.

In its 75 years history, Penn Ventilation has grown from a three-man operation in a small sheet metal shop in Philadelphia, Pennsylvania to a full line ventilation manufacturing company. An industry innovator, Penn Ventilation offers a broad range of centrifugal roof and wall fans, propeller fans, blowers, inlet hoods, and gravity ventilators.

Contact Fluid Engineering today for assistance with new equipment or with help servicing an existing Penn Ventilation fan.

PENN

PENN

Ventilation Systems

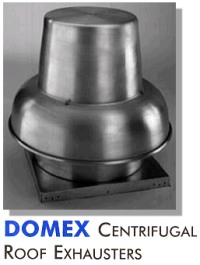

Domex fans are ideal for general purpose exhaust applications including: bathrooms, garages, general kitchen areas, offices, churches, dormitories, factories, large warehouses and other relatively clean air applications.

They feature a weather-resistant seamless spun aluminum housing which works in conjunction with a patented wheel design and deeply spun inlets to provide smooth quiet air flow through the ventilator.

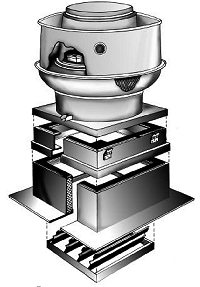

DOMEX Centrifugal Roof Fans

Domex centrifugal fans are designed for roof-mounted installations in low to medium pressure applications. They are available in a range of capacities:

DIRECT DRIVE

Direct drive models with performance to above 3000 CFM

STANDARD DUTY BELT DRIVE Belt drive models with performance to above 20,000 CFM

HIGH CAPACITY BELT DRIVE Belt drive models with performance to above 46,000 CFM

HIGH CAPACITY BELT DRIVE Belt drive models with performance to above 46,000 CFM

The centrifugal wheels are aluminum, non-overloading, backwardly inclined, robotically welded, and dynamically balanced. All models have been rigorously tested in our state-of-the-art R&D lab.

Penn Ventilation is registered for AMCA Air and Sound testing and qualified for the Underwriters' Laboratory Client Test Data Program. Designed for easy maintenance accessibility, Domex fans accommodate a wide variety of motor types. All units are fully assembled and test run prior to shipping. Belt drive models are pre-set to the RPM specified.

PENN

TMVentilation Systems

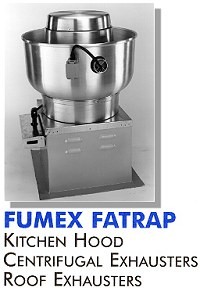

Fumex centrifugal fans are designed for medium to high pressure applications. They can be either roof or wall mounted. While suitable for general ventilation, Fumex fans are specifically designed to discharge contaminated or grease-laden air or fumes up and away from building surfaces. The optional "Fatrap" (UL762) restaurant grease exhaust configuration (see Options and Accessories section) makes Fumex fans particularly suited for all food service applications and chemical fume hoods.

FUMEX

FUMEX

Centrifugal Exhausters

All models have been rigorously tested in our state-of-the-art R&D lab. Penn Ventilation is registered for AMCA Air and Sound testing and qualified for the Underwriters' Laboratory Client Test Data Program. Fumex fans are available in a range of capacities:

MOTOR SELECTION

Both direct drive and belt drive models are available with a wide range of voltages and enclosures. Standard belt drive Open Drip Proof (ODP) ball bearing motors are selected using a conservative portion of the NEMA service factor. Standard direct drive ODP motors have Class B insulation and internal overload protection. Each size is carefully engineered to match the motor to the wheel capacity.

INTERNAL WIRING All direct drive models with ODP motors feature a polarized disconnect plug between the motor and junction box. This provides a positive method of electric shut-off as required by most codes without requiring the traditional electric disconnect switch. An electric disconnect is available (see Options and Accessories section.) Belt drive units have a NEMA 1 disconnect switch and junction box that are factory-wired to the motor.

SOUND PERFORMANCE Lowest AMCA licensed sound performance in the industry. Units deliver outstanding air performance with minimal noise.

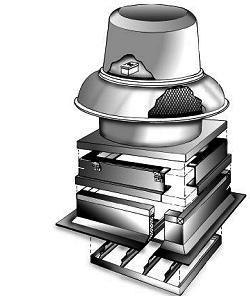

SOUND PERFORMANCE Lowest AMCA licensed sound performance in the industry. Units deliver outstanding air performance with minimal noise.STRUCTURAL INTEGRITY Durable housings of spun aluminum have a high strength-to-weight ratio and incorporate a rolled bead for additional strength. There are no welds to break or seams to leak. The heavy-gauge motor mounting platform provides positive rigidity between all components of the power train assembly.

INTERNAL BRACING Tri-Strut™ supports transfer the weight of the motor mounting platform directly to the curb mounting surface. The aluminum spun housing, therefore, is not used to support any weight. For grease laden applications, there is less surface for grease build-up during normal operation.